Hydraulic integrated systems are the core power units of today's mobile equipment or mechanical processing, and are widely used. Industrial applications include hydraulic stamping machines, rolling equipment, injection molding machines, bending machines, fatigue testing machines, testing and inspection equipment, CNC machine tools, CNC machining centers, automatic packaging lines, conveying systems, storage systems, etc. For example, in order to cope with high energy consumption, high impact, prevent failures, and reduce maintenance costs, intelligent hydraulic stations use pressure, temperature, liquid level and other sensors to monitor their internal performance and ensure operational reliability.

Reliability monitoring makes system operation more efficient

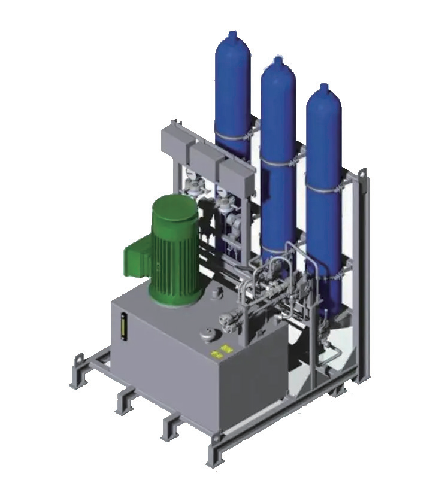

A hydraulic station is a highly integrated hydraulic system designed to improve energy efficiency and reduce operating costs. The equipment is usually composed of a hydraulic pump, hydraulic valve, motor, oil storage tank and control system, and uses advanced frequency conversion technology and intelligent control systems. To ensure stable and efficient operation of the equipment, we optimize the performance of the entire hydraulic station by monitoring key parameters such as temperature, vibration, pressure, flow rate and oil level.

Hydraulic Electronic Digital Presuure switchMD-S853

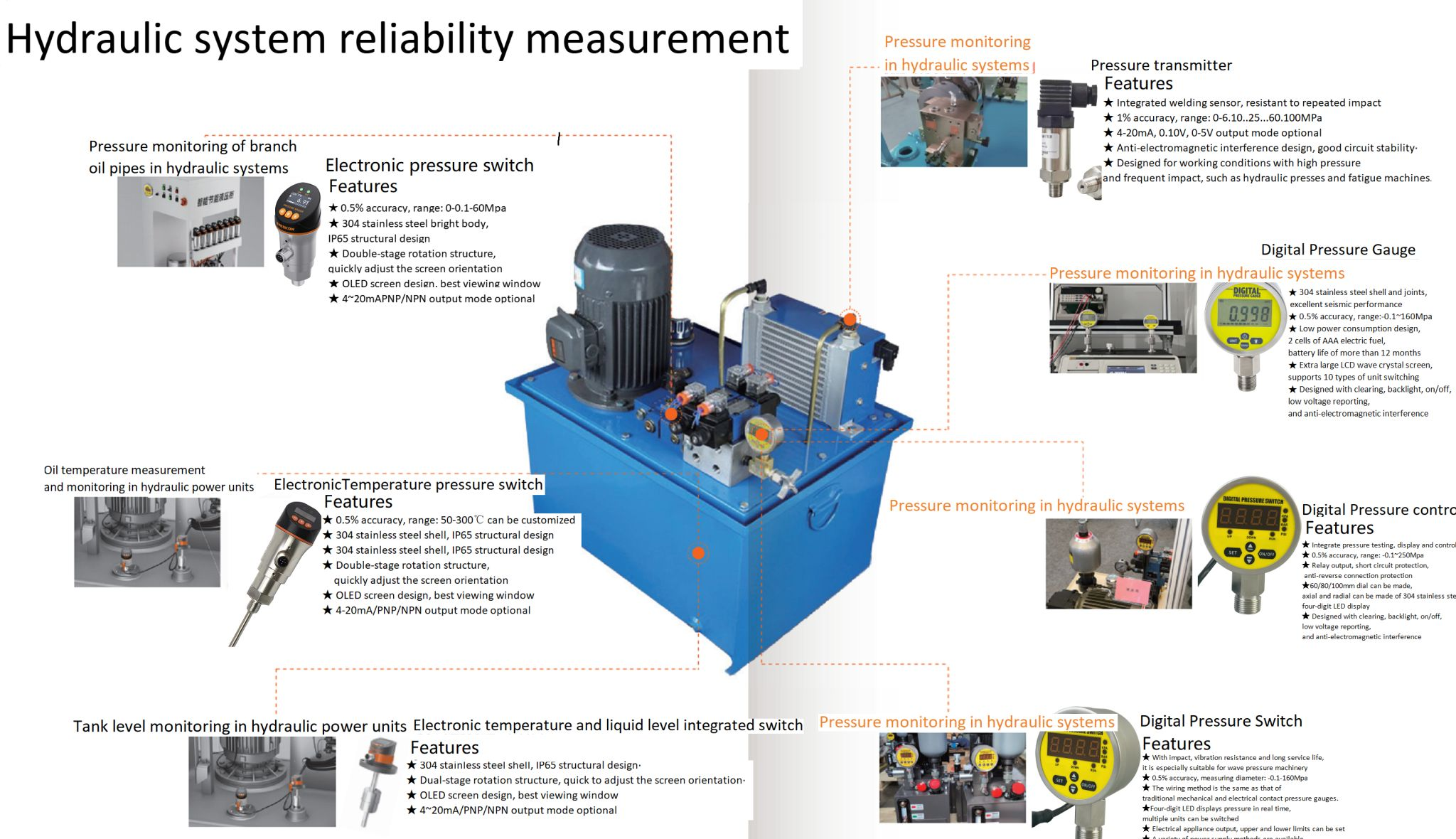

The pressure of the hydraulic system directly affects the power transmission of the equipment. Real-time monitoring of pressure can ensure that the system works as required and avoid excessive energy consumption or performance degradation caused by too high or too low pressure.

Excessive temperature of hydraulic oil will reduce system efficiency and accelerate equipment wear. By monitoring the temperature in real time, we can prevent the hydraulic oil from overheating and ensure that the hydraulic system always operates within the optimal temperature range

The change of the liquid level in the hydraulic oil tank directly affects the safety and operation stability of the system. Too low oil level may cause air to enter the system, causing damage to the hydraulic equipment.

Hydraulic system reliability measurement

▶▷Product Recommendations

Reliability measurement of hydraulic systems is not only a technical issue, but also the key to improving efficiency and reducing costs for enterprises. Through scientific measurement methods and advanced industry solutions, we can escort equipment operation and help enterprises achieve efficient and stable production goals.

If you are interested in hydraulic system reliability measurement, or want to obtain customized solutions, please contact us

Post time: Mar-17-2025