Science and technology are changing with each passing day. High-precision industrial production environments, pharmaceutical and food production environments, and harsh medical environments have increasingly higher requirements for air cleanliness. Class 100, Class 1,000, Class 10,000, and Class 100,000 clean rooms are crucial for monitoring tiny airflows.

In the design, construction and operation of clean rooms, it is necessary to reduce the interference of the surrounding environment to the clean room, and pressure difference control is an important and effective means to maintain cleanliness levels, reduce external pollution, and prevent cross-contamination. Today, let’s talk about the application of digital differential pressure gauges in clean rooms.

Detection method of micro differential pressure

The measurement of static pressure difference requires all doors in the clean area to be closed.

It should be carried out in order from high to low cleanliness, all the way to the rooms with direct access to the outdoors. The measuring tube mouth is located anywhere in the room without the influence of air flow, and the measuring tube mouth surface is parallel to the air flow streamline. The measured and recorded data should be accurate to 1.0Pa.

Micro pressure difference detection steps

Close all doors first.

Use a digital differential meter to measure the pressure difference between clean rooms, between clean room corridors, and between corridors and the outside world. and log all data.

Micro pressure difference standard requirements

Clean room design or process requirements determine the positive or negative pressure value maintained in the clean room under test.

1.The static pressure difference between clean rooms or clean areas of different levels and non-clean rooms (areas) should not be less than 5Pa.

2.The static pressure difference between the clean room (area) and the outdoors should be no less than 10Pa.

3.For unidirectional flow clean rooms with air cleanliness levels stricter than Level 5 (Level 100), when the door is opened, the dust concentration on the indoor working surface 0.6m inside the door should not be greater than the dust concentration limit of the corresponding level. If the requirements of the above standards are not met, the fresh air volume and exhaust air volume should be readjusted until they are qualified.

| Grade | per m³/L ≥0.5μm in air Number of rice grains |

per m³/L ≥5μm in air Number of rice grains |

| 100 | ≤35×100 (3.5) | |

| 1000 | ≤35×1000 (35) | ≤250 (0.25) |

| 10000 | ≤35×10000 (350) | ≤2500 (2.5) |

| 100000 | ≤35×100000 (3500) | ≤25000 (25) |

In which clean rooms are digital differential pressure gauges mainly used?

01 .Pharmaceutical factory clean room

Digital differential pressure gauges can help monitor and control the pressure differential inside the clean room of a pharmaceutical factory to ensure the cleanliness and safety of the production environment, thereby ensuring the quality and compliance of pharmaceutical production.

02. Hospital clean ward

The digital differential pressure gauge can use the difference in air pressure inside and outside the ward to ensure that the air quality meets medical and health standards, prevent external pollutants from entering the ward, and provide a safe and clean environment for patients and medical staff.

03. Electronic workshop clean room

The digital differential pressure gauge can help monitor and control key parameters such as air quality, filtration effect and wind speed in the clean room of the electronic workshop, thereby maintaining the cleanliness and environmental control in the clean room of the production workshop and ensuring the quality and production safety of electronic products.

04. Experimental clean room

The digital differential pressure gauge can be used in experimental cleanliness to measure the differential pressure in the clean room in real time and accurately, providing operators with appropriate adjustment reference to ensure that the positive and negative pressure differences in the clean room always meet the requirements.

What are the common digital differential pressure gauges used

in clean rooms?

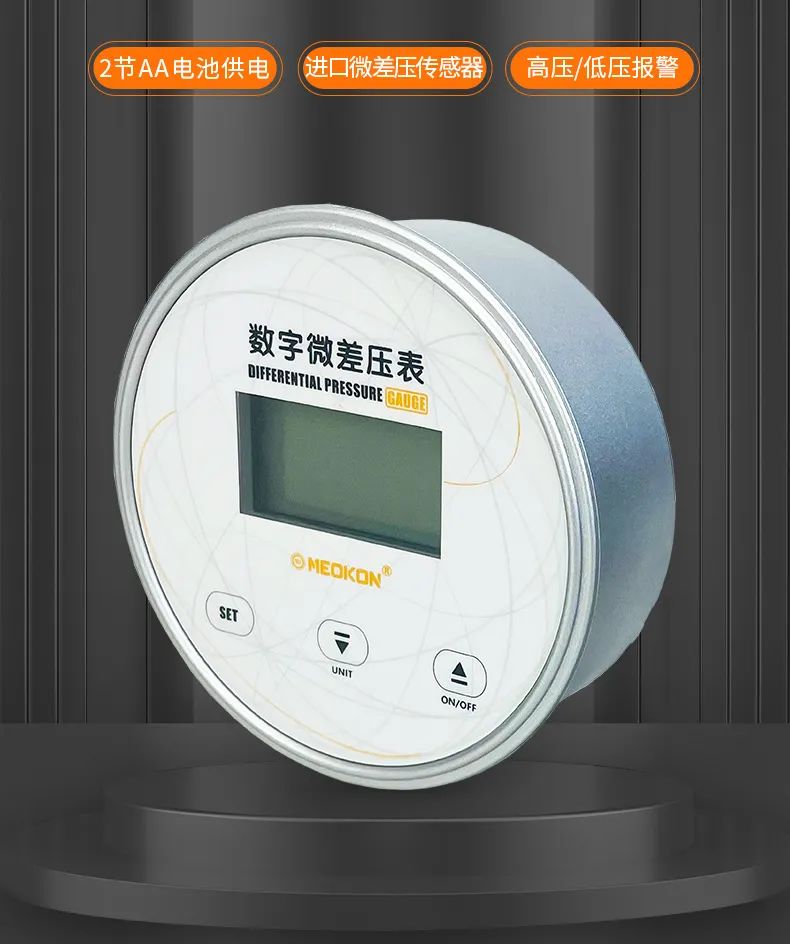

MD-S220 digital differential pressure gauge

The original imported micro-differential pressure sensor is used as the pressure-sensing element, and combined with an ultra-low power consumption digital conditioning circuit, it has the characteristics of high precision and good long-term stability.

MD-S221 Digital Micro Differential Pressure Transmitter The original imported micro-differential pressure sensor is used as the pressure sensing element, and RS485 or 4-20mA output can be selected according to needs.

Post time: Sep-20-2023