2.png) |

1.png) |

.png) |

Meokon Sensor New Product Gas Safety Monitoring Series

MD-S975 gas flow monitor

- Big launch -

This new gas flow monitor corresponds to the range and installation method according to the design of the kiln pipeline. It is particularly suitable for monitoring the conditions of cooling gas (such as air and nitrogen) in the kiln pipeline, replacing the original mechanical float flow meter. In addition, it can also be used in laboratory chemical reactions or material testing, semiconductor production processes, and process control in petrochemical, metallurgy, and welding.

Meokon MD-S975 gas flow monitor

Accuracy level of ±2%FS

Better than traditional float flow meters

Maximum flow rate up to 1700 SLM

Adapt to the detection needs of various gas flow rates

Gas medium can be switched by pressing the button

You can turn on the rotation mode at any time. The dial rotates horizontally 270° to adapt to different installation needs and angles. The difficulty of installation and maintenance plummets.

Made of polyester plastic and aluminum alloy, it is larger and heavier than traditional mechanical flow meters. The minimum volume is 159cm.

Taking 400SLM equipment as an example, the total product weight is 173g.

Volume 170cm3

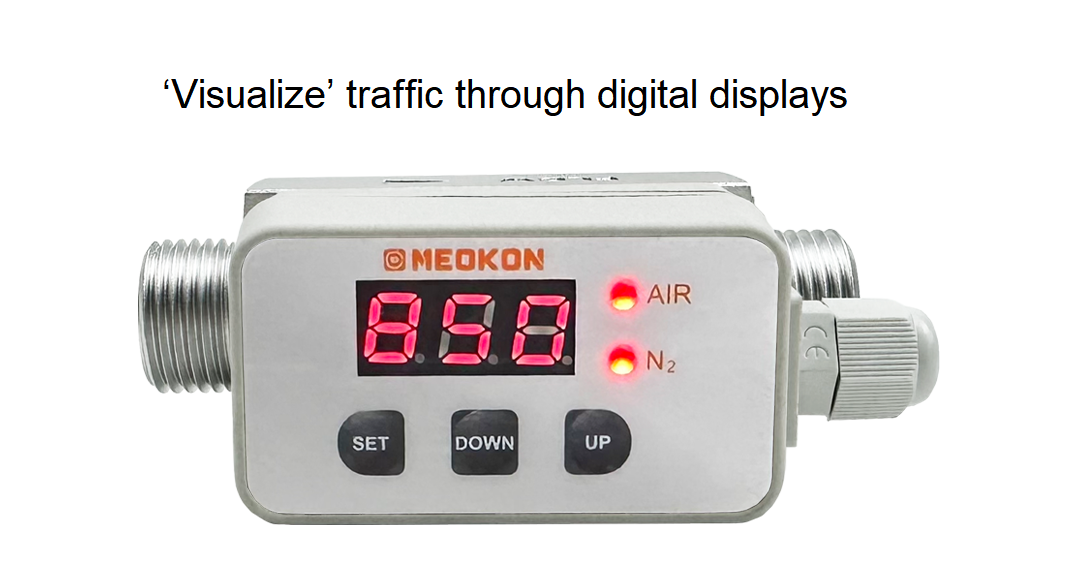

Provide digital interface and communication protocol 4-20mA/RS485 optional

Support remote monitoring and control to meet the needs of modern digital monitoring and control. It also supports Shuning display to make flow visualization operations more convenient and worry-free.

“Visualize” traffic through digital display

Knowledge tips:

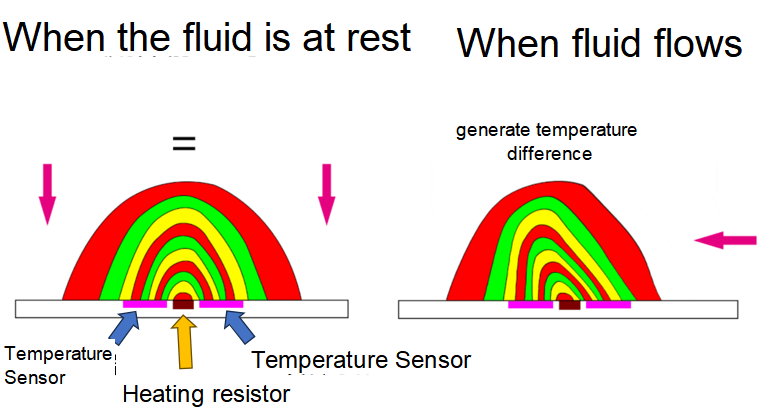

Thermal mass flow meter. (hereinafter referred to as TME) is an instrument that uses the heat transfer principle, that is, the heat exchange relationship between the flowing fluid and the heat source (a heated object in the fluid or a heating body outside the measuring tube) to measure flow. It is currently mainly used to measure gases.

During measurement, the two sensors will be placed in the gas to be measured at the same time. One sensor will be heated, and the other will be used to sense the gas to be measured. The increase in the gas flow rate will take away too much heat and cause the sensor temperature to drop. , by calculating the relationship between flow rate and temperature, the current flow value of the fluid is obtained

Post time: Nov-24-2023