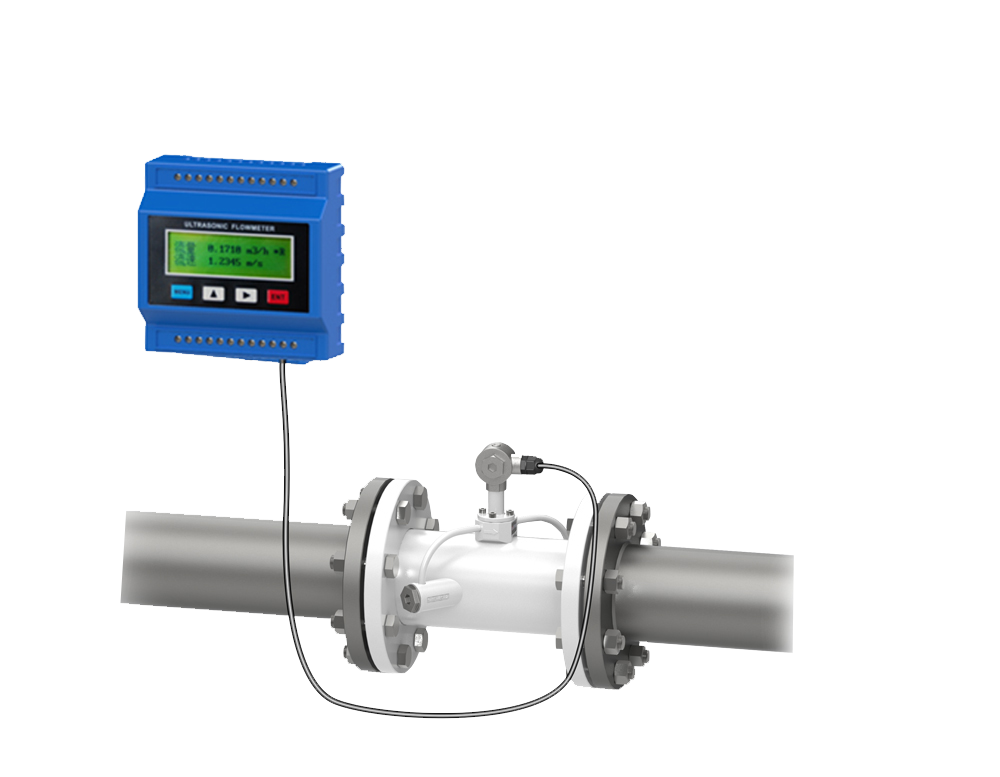

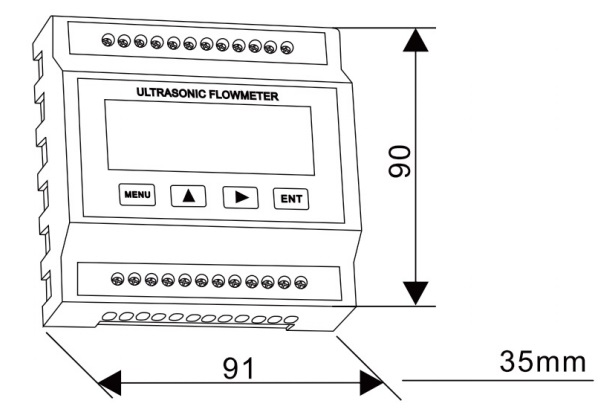

MD-S462 Pipe segment ultrasonic flow meter

Tech Features:

The measurement results are not affected by physical properties such as temperature, pressure, viscosity and density.

Pipe segment ultrasonic flowmeter is suitable for various pipeline flow measurement, and the flow rate measurement range is 0.01~+10m/s. Temperature, pressure, viscosity and density have no effect on the measurement results. The medium to be measured can be water, seawater, sewage, acid and alkali liquid, alcohol, beer, various oils and other single uniform liquids that can transmit ultrasonic waves.

The pipe material to be measured can be stainless steel, cast iron, copper, PVC, aluminum, glass and other mass-tight pipes. Village pipe segment ultrasonic flowmeters are allowed, which can be used immediately after installation and power-on without additional parameter settings. No need to select additional sensor installation points, stable and reliable, no pressure loss, low starting flow meter.

Applications :

Heating and heating industry

water supply

Calorie metering charges

Water treatment industry

fuel oil light oil

Chemical materials.

Tech Features:

| Flow rate range | 0~±10m/s, forward and reverse measurement |

| Accuracy level | 1%FS |

| Pipe diameter | DN15~DN1000,or customized |

| Fluid temperature | ‘-30°C~160°C |

| Signal output | RS485, 4-20mA, relay output |

| Power supply | 12~28VDC |

| Operating temperature | -30°C~160°C (sensor), -20°C~60°C (host) |

| Working humidity | 0-100%RH(传感器), ≤80%RH (host) |

| Fluid type | Water, seawater, sewage, acid and alkali liquids, alcohol, beer, various oils and other single uniform liquids that can transmit ultrasonic waves. |

| Pipe material | Stainless steel, cast iron, copper, PVC, aluminum, glass and other quality-tight pipes are allowed to be lined. |

| Protection level | IP68(sensor) |

| Installation method | External clip-on |