MK-PC106 Hydraulic pressure comparators /pump/ pressure tester/Oil Deadweight Testers/comparison test pump

1. Overview

Pressure calibration table (hereinafter referred to as calibration table) is an important auxiliary equipment in the measurement of pressure instruments. Cooperate with the pressure standard to complete the calibration and test of the pressure instrument.

It is widely used in measurement, scientific research, industrial and mining enterprises, instrument manufacturing and other industries.

2. Features

2.1 open structure, all spare parts and pipelines are combined on the front side for easy maintenance.

2.2 large volume chamber, wide stroke lever type pressure making pump, easy to make pressure and fast to pressurize.

2.3 with the successful application of CNC turning, milling and grinding technology, the product has high precision and good performance.

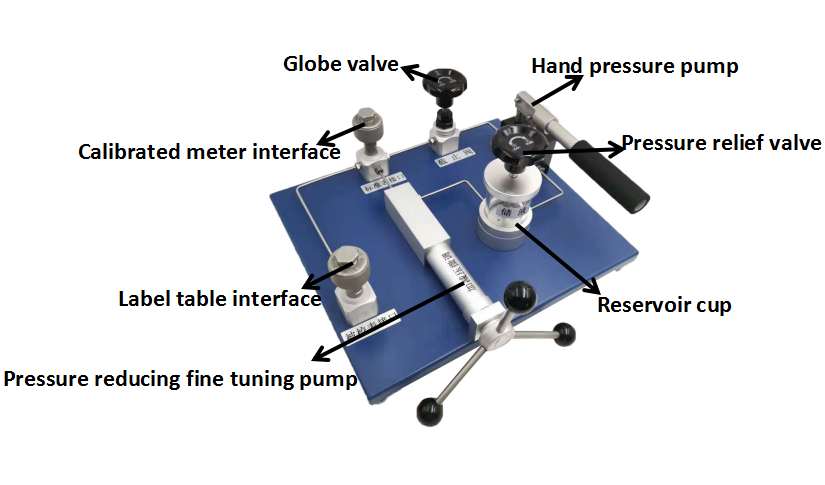

3. structure name and function

The lever drives the piston of the large chamber to move back and forth to generate pressure, which is fine adjusted to the pressure output through the stop valve. The required pressure is completed by monitoring the standard gauge, and then fine adjusted to the inspection point.

4.Operation and use

Pressure detection

4.1 First, connect the tested meter to the output port of the tested meter, connect the standard meter to the output port of the standard meter, open the stop valve and the oil cup pressure relief valve, and turn the fine adjustment of pressure and pressure to the bottom counterclockwise, and make pressure 10 times through the hand pressure pump to exhaust the air in the testing instrument system.

4.2 Close the pressure relief valve of the oil cup, pressurize it to about 5-20MPa with the hand pressure pump, then close the stop valve, and pressurize it to the detection pressure point by adding pressure reduction fine adjustment.

4.3 When the calibrated meter is rechecked, the counter clockwise rotation shall be adjusted by adding and reducing pressure, and the point by point detection shall be conducted by reducing pressure.

4.4 At the end of calibration, open the relief valve first, and then the stop valve.

5. Precautions

5.1 the calibration platform shall be placed on a stable operation platform to avoid entering the environment with corrosive gas and dust particles.

5.2 the output is a special fast interface face seal. When installing the instrument, it is not necessary to use any tools to tighten it evenly. After the sealing surface contacts with the sealing ring surface, it can be screwed again. (ensure that the calibrated meter is clean and clean)

5.3 the lever is pressurized and the application force is even!

6. External structure